Reaktor tekanan pengangkat listrik 30L

Reaktor tekanan angkat listrik | Dudukan lantai atau jenis kereta yang dapat dipindahkan/ Reaktor tekanan laboratorium/ Pabrik reaktor percontohan/ Reaktor tekanan percontohan/ Autoklaf bertekanan, Sesuaikan 20 liter - 50 liter, Tekanan maksimum 120bar, Suhu maksimum hingga 250C.

- HXCHEM

- Cina

- 10 hari setelah pembayaran

- 30 set/bulan

Detail

30L electric lifting pressure reactors

Pilot pressure reactor/ autoclaves

Introduction

This kinds 30liters autoclaves equipped with belt driven magnetic coupling agitator, pressure maximum up to 120bar, temperatrue up to 300C, the wet material fabricate in SS316L. High efficiency hollow gas induction impellers design help this autoclave applicated in hydrogenation or gas-liquid reaction. This series stirred pressure autoclave is widely used in laboratory or pilot plant reactors.

Features

Volume: 20liters, 30liters, 40liters

Maximum pressure: 120bar

Mximum temperature:300C

Material: SS316L

Magnetic coupling driven agiator

Internal cooling coils, dip tube, shaft, gas induction impeller

Electric crain lifting devices for heavy lid lifting and lowering.

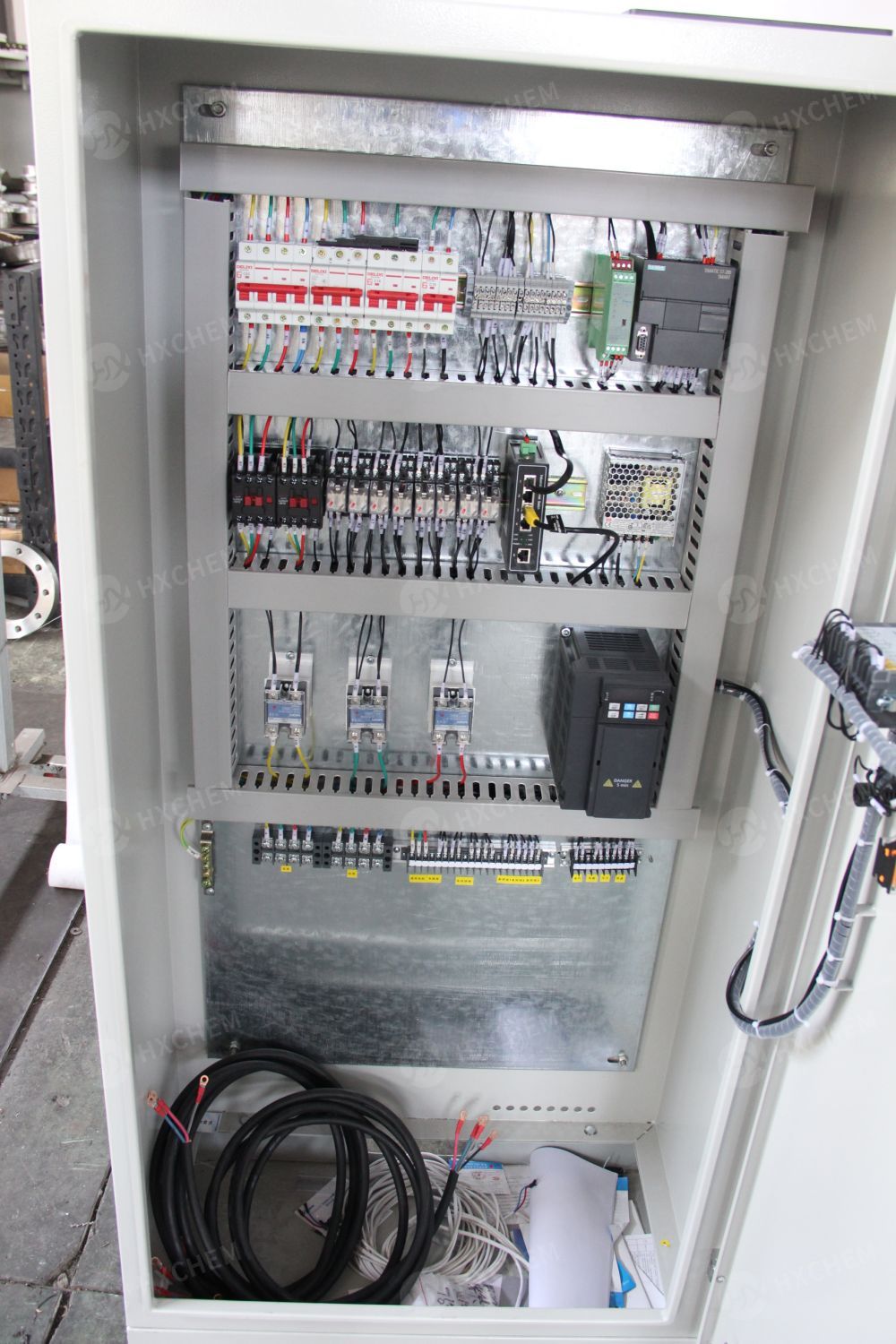

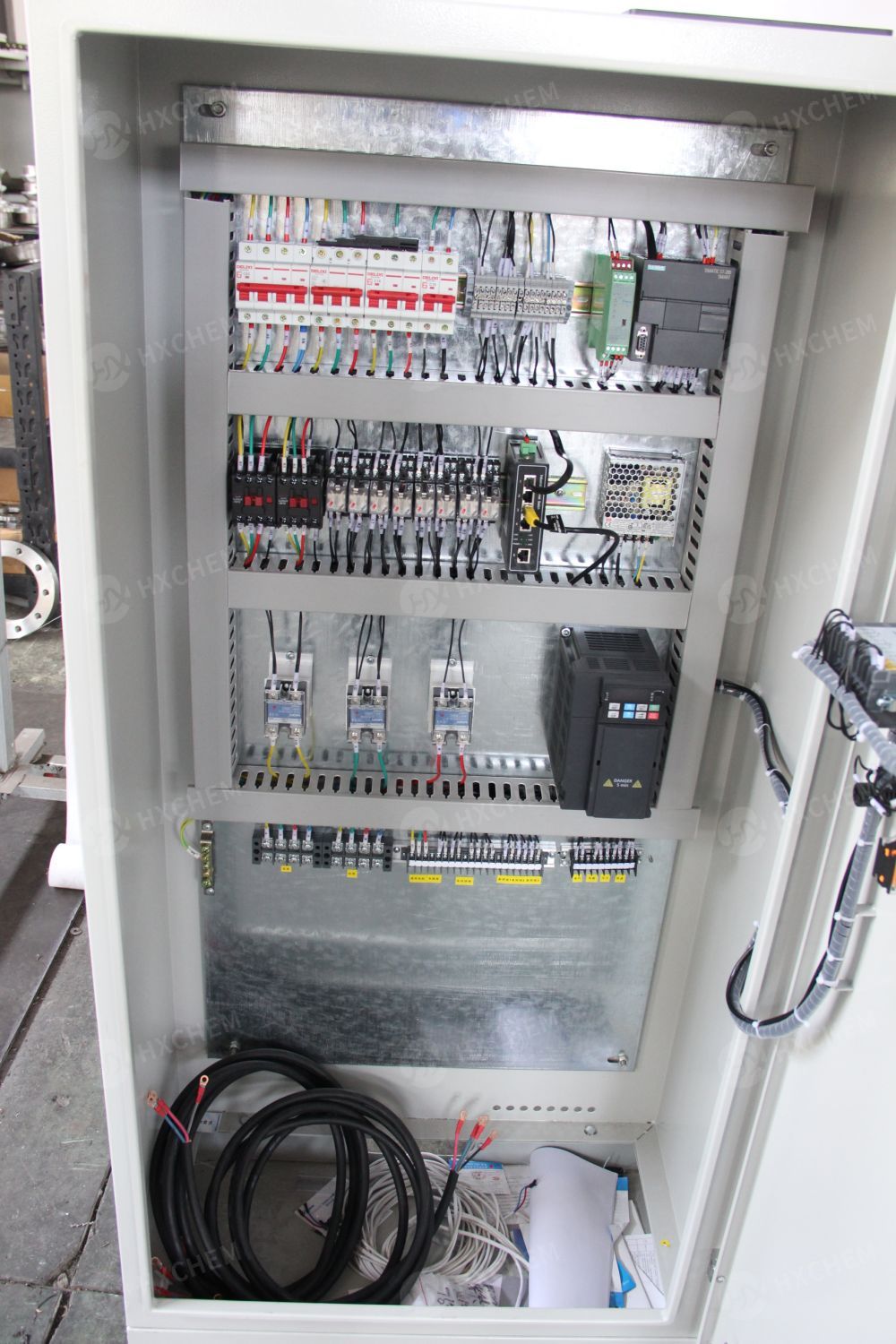

PLC touch screen control cabinet:

Temp. pressure display and data record. Temp. pressure alarm

Standard specfications

GSH lifting reactor standard specification table.

| Model No. | GSH-5 | GSH-10 | GSH-20 | GSH-30 | GSH-40 | GSH-50 |

| Nominal Capacity | 5liters | 10liters | 20liters | 30liters | 40liters | 50liters |

| Max Working Pressure | Standard 100bar; Max pressure up to 250bar | |||||

| Working Temperature | Standard 350°C;Up to 500°C | |||||

| Stirring Speed | 0-750rpm | 0-500rpm | ||||

| Motor Power | 600W | 600W | 1.1kW | 1.5kW | 1.5kW | 3KW |

| Heating Power | 4kW | 9kW | 9kW | 12kW | 12kW | 15kW |

| Closure | Flange bolts closure/ Clamp closure | |||||

Lifting & lowering | Manual crain lifting/ Electric crain lifting | |||||

| Material | SS304,SS316 or other alloys(Titanium, hastelloy, Inconel, Nickel, etc) | |||||

| Heating Method | Electric heating or Jacket heating | |||||

| Cooling | Internal spiral coils(Optional) | |||||

| Charging Method | Up discharge by pressure or discharge by bottom valve | |||||

| Impeller (Optional) | Propeller, paddle type, turbine, anchor type, gas induction, helix type, etc. | |||||

| Control panel | Temp.display and control, accuracy+ 1℃, Stirring speed display & control Touch screen program control(Optional) | |||||

| Standard fittings | Pressure Gage, Thermocouple, Central stirring port Liquid inlet/ Sampling port with needle valve & dip tube and gas inlet with needle valve Safety Rupture Disc: Internal cooling Coil(Optional); Solid feeding plug(Optional) | |||||